Early Invention (Mid-1800s)

1856 (England): Corrugated paper was first patented by Edward C. Healey and Edward G. Allen as a liner for tall hats, providing stiffness and cushioning.

1871 (USA): Albert L. Jones of New York patented single-face corrugated board — originally used as a packaging wrap for glass and bottles.

1874: Oliver Long improved the design by adding liners to both sides, creating the corrugated board we know today.

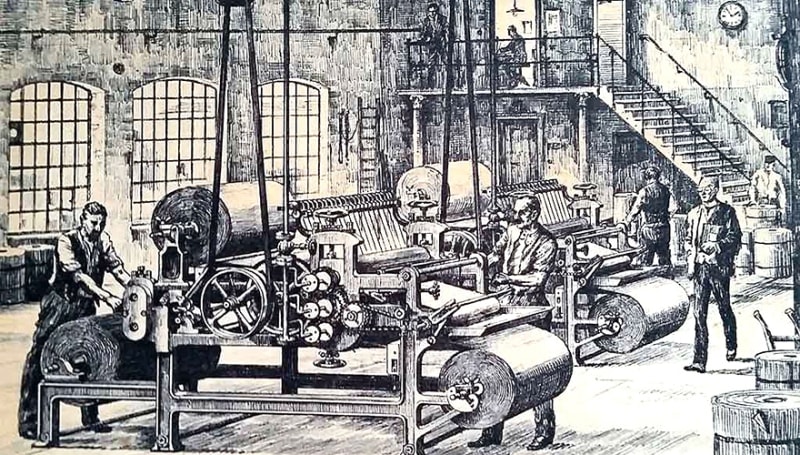

Industrial Growth (Late 1800s – Early 1900s)

1890s: Corrugated boxes began replacing wooden crates for shipping because they were lighter, cheaper, and more protective.

1895: First corrugated box manufactured in the U.S.

1903: Robert Gair (credited with inventing the pre-cut paperboard box in 1890s) applied die-cutting and mass production techniques to corrugated board.

1909: Fibre Box Association (originally called the “National Container Association”) was established in the U.S.

Mass Adoption & Standardization (1920s–1940s)

1920s: Corrugated boxes became the dominant shipping container, especially with the growth of railroads and later trucking.

1930s: Standardization efforts began; organizations like TAPPI (Technical Association of the Pulp and Paper Industry) established testing methods.

WWII (1940s): Corrugated boxes played a crucial role in supplying war goods — lightweight, stackable, and durable.

Post-War Expansion (1950s–1970s)

1950s: Explosive growth in consumer goods increased demand for corrugated packaging.

1960s: Flexographic printing developed, enabling branding and graphics directly on corrugated surfaces.

1970s: Corrugated boxes became the primary packaging choice worldwide, with innovations in multi-color printing and stronger board grades.

Sustainability & Globalization (1980s–2000s)

1980s: Lightweighting advances improved strength-to-weight ratios.

1990s: Recycling became a central theme; corrugated board recycling rates surged as municipalities expanded collection programs.

2000s: Global trade growth boosted demand; major integrated paper/packaging companies expanded worldwide.

Modern Era (2010s–Present)

2010s: E-commerce boom (Amazon, direct-to-consumer brands) dramatically increased corrugated packaging demand, especially custom-sized boxes.

2015–2020: Digital printing on corrugated (EFI, HP PageWide, Barberán presses) allowed high-graphic, short-run customization for brands.

2020s: Sustainability became the top priority — circular economy, recyclable coatings, reduction of plastics. Corrugated remains one of the most recycled packaging materials (>90% recovery in the U.S.).

Today: Industry innovation focuses on:

Automation & robotics in box-making.

AI-driven design for right-sizing packaging.

Water-based inks & coatings for greener printing.

Global supply chain resilience after COVID-era disruptions.

✅ Summary:

In under 150 years, corrugated packaging went from a hat stiffener to the world’s dominant packaging solution, evolving through inventions, war logistics, consumer goods growth, e-commerce, and now sustainability and digital printing. It remains at the center of global trade and retail packaging.